Modalal Polymer Baft

Professional Manufacturer of Standard Bags and Cement Sacks

History of AD*STAR Cement Sack

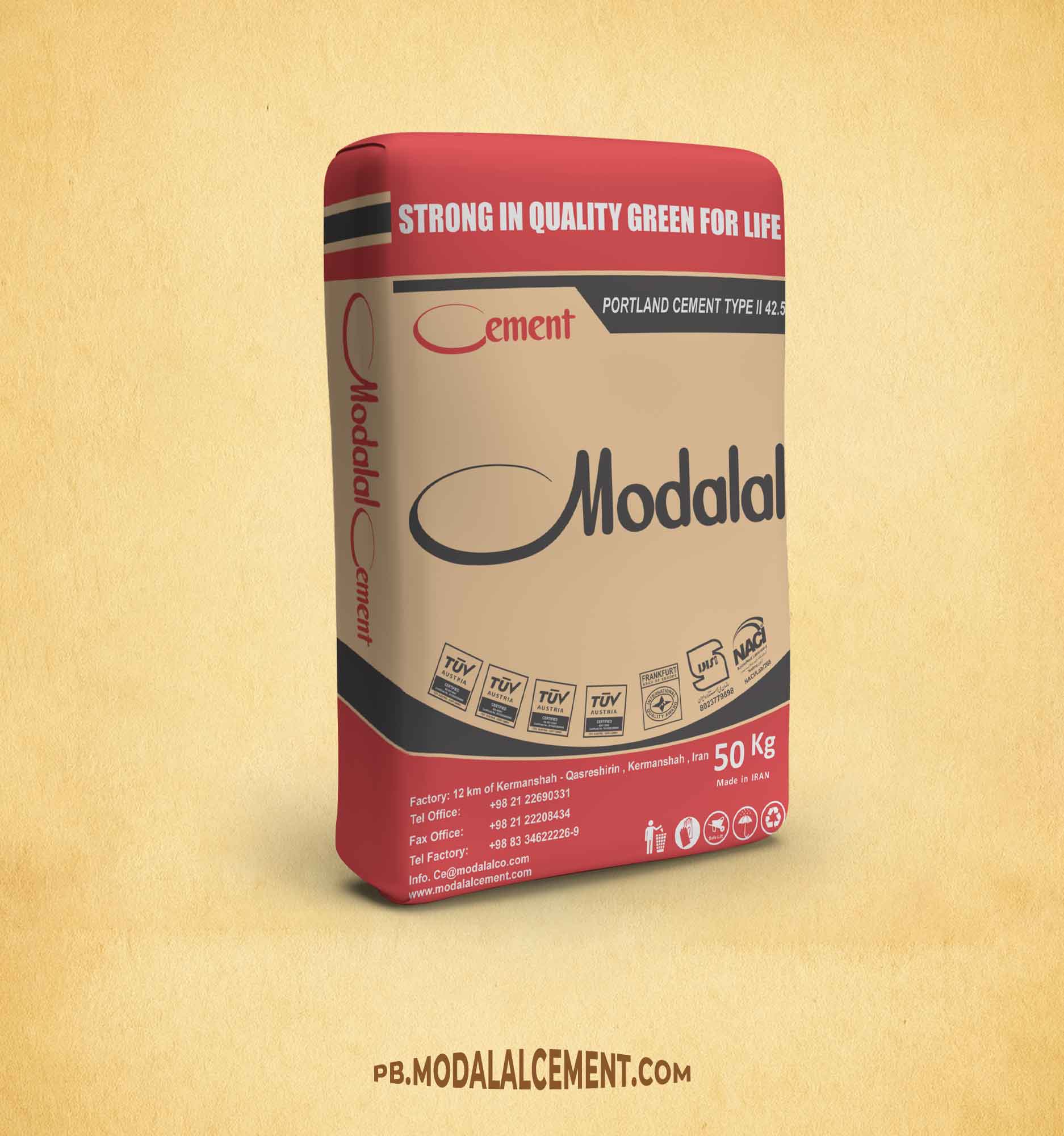

Until the 1990s, most cement packaging worldwide was done using multi-layer paper bags. Over time, these bags caused major problems, including tearing during transportation, moisture penetration, excessive dust, and high levels of waste. These challenges led the Austrian company Starlinger to pursue innovation in the cement packaging industry.

The result of years of research and development was the introduction of AD*STAR sacks—an exclusive technology patented in the early 1990s. These sacks are made from woven polypropylene fabric and are sealed using heat and pressure instead of stitching. This method provides exceptional strength, high resistance to moisture, and a longer service life.

Due to its recyclability and environmental compatibility, the AD*STAR sack gained special popularity and was rapidly adopted by the cement industry, eventually becoming the global standard for cement packaging.

Get to Know Cement Sacks;

Features and Benefits You Didn’t Know!

- Available in a Variety of Colors

- Optimized bag weight (approximately 70 grams)

- Up to 6-Color Printing Capability

- Suitable for Repeated Loading and Unloading

- Produced without the use of adhesives

The AD*STAR sack represents a distinguished example of advanced packaging technology. Through the intelligent selection of woven polypropylene materials and an innovative seamless design, it delivers exceptional strength, stability, and quality. In addition to economic efficiency, these sacks offer high-quality multicolor printing and reliable protection against moisture and environmental factors. An ideal choice for cement packaging, this sack combines superior performance with visual appeal.

Its stitch-free structure and flat bottom enable faster and easier cement filling while preventing leakage and material loss. In addition to high strength, this sack allows for neat stacking and easy handling during transportation.

Applications of AD*STAR Sacks:

- Cement and Construction Materials Industries: For packaging cement, gypsum, and other powdered construction materials that require protection against moisture and tearing.

- Chemical and Mineral Industries: Suitable for chemical powders, mineral materials, and additives where precision and safety in transportation are essential.

Polymer and Petrochemical Materials: For polymer granules and raw polymer materials that require durable packaging throughout the supply chain.

History of the Standard Sack:

In the not-so-distant past, products such as flour, sugar, refined sugar, and livestock feed were packaged and transported using Jute, linen, and handwoven sacks In the not-so-distant past, hemp, linen, and handwoven sacks were used for packaging and transporting products such as flour, sugar, and animal feed. Although these sacks played an important role in storage and transportation, their heavy weight, susceptibility to moisture, and limited durability posed serious challenges for both producers and consumers.

With the advent of Synthetic fibers and polypropylene With the introduction of synthetic fibers and polypropylene in the second half of the twentieth century, the packaging industry underwent a fundamental transformation. Woven polypropylene sacks gradually replaced traditional bags and gained widespread popularity due to their high strength, lightweight nature, and the ability to be produced in various sizes.

Over time, the one-meter dimensions Over time, the one-meter size became established as the reference standard for many food and livestock industries. This choice not only facilitated transportation and storage, but also provided an appropriate capacity (approximately 40 to 50 kilograms) to meet the needs of a wide range of industries.

Today, the one-meter standard sack, after undergoing its historical evolution, remains the most widely used type of packaging in sectors such as flour, sugar, and livestock and poultry feed, playing a vital role in the supply chain of the food and agricultural industries.

Features of the Standard Sack:

Standard sacks go beyond simple packaging; they are a reliable shield for your industrial products. Lightweight yet exceptionally durable, these sacks securely protect even the heaviest loads such as cement, gypsum, and flour.

With a precise, tear-resistant woven structure, they offer exceptional resistance to moisture, abrasion, and pressure, while their surface enables high-quality printing of logos and brand information—ensuring your products always look professional.

Gusseted and non-gusseted models can be produced according to customer requirements.

Gusseted Bag (Gusseted Bag) : With folded edges for increased capacity and a stable rectangular shape, making it suitable for easy storage and transportation of products.

Flat Bag Simple and single-layer, suitable for fast packaging with easy stitching, ideal for products with lower volume.

Applications of Standard Bags:

Food Industry: Flour, Sugar, Rice, and Legumes

Food Industry:Flour, Sugar, Rice, and Legumes

Agriculture and Fertilizer Industries:Chemical fertilizers and feed grains

Chemical and Industrial Industries:Powdered and Granular Materials

Types of Standard Sacks:

- Available in a Variety of Colors

- Can be produced in widths ranging from 35 to 80 centimeters

- Laminated (waterproof) and non-laminated (standard)

- Gusseted (folded edges) and non-gusseted (flat)

Why Choose Us

- Modalal factories are among the consumers of standard sacks and cement bags; accordingly, Modalal Polymer Baft applies the same standards it selects for its own internal use to products offered to other customers as well.

- With the presence of the Modalal HIGH-TECH Laboratory, specialized tests are conducted on yarns, fabrics, and sacks. At every stage of production, thorough inspections ensure that any defects are promptly identified and corrective actions are immediately taken.

- The raw materials used in the yarns are of the highest quality, resulting in the production of fabrics with a uniform and consistent weave.

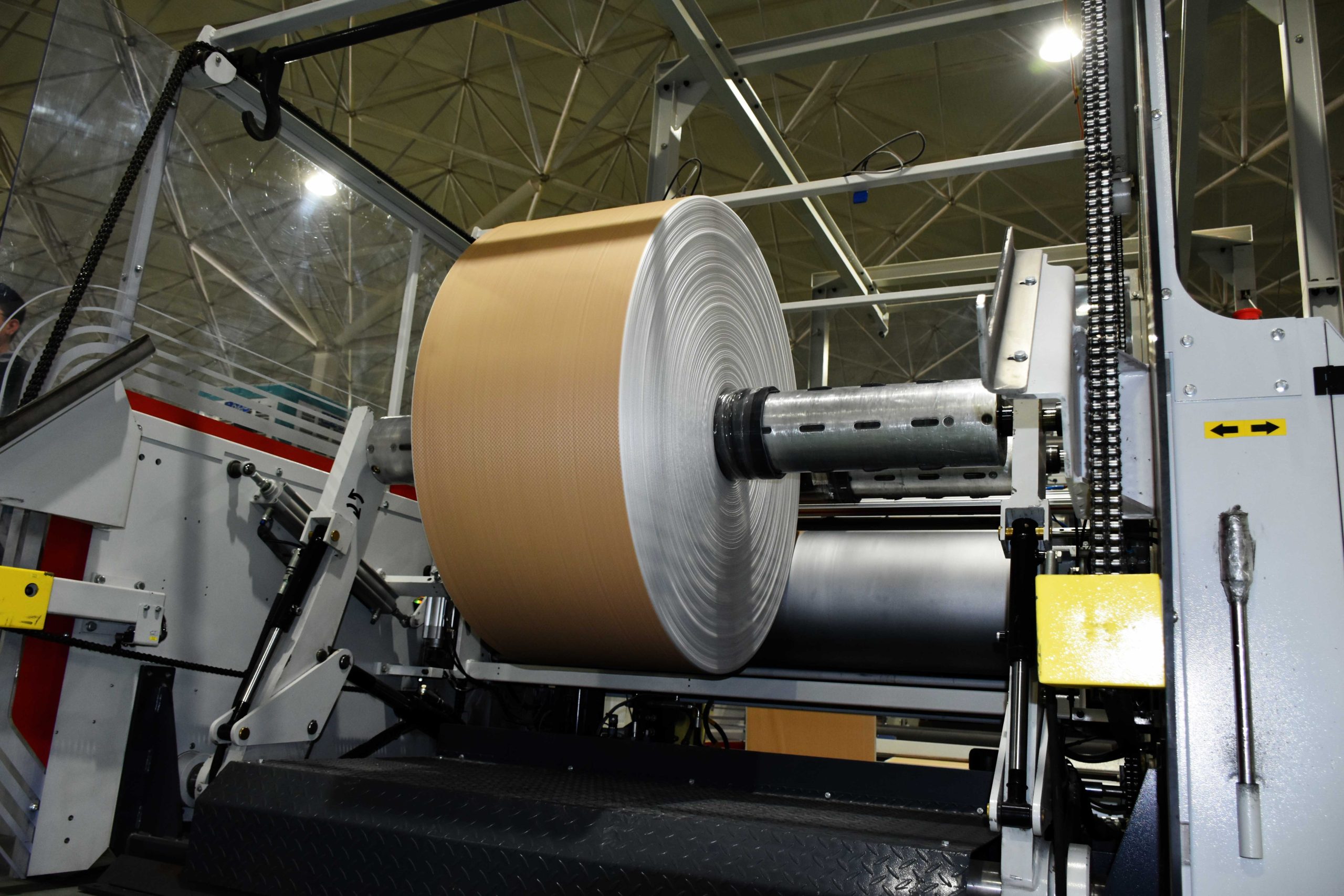

- Modalal Polymer Baft Factory is equipped with the latest and most advanced bag and sack production machinery.

- With the use of STARLINGER Dynaflex and Rollflex machines, print quality is exceptionally high, resulting in bags with very fine print resolution at a 0.25 mm screen (dot) size.